“Innovation distinguishes between a leader and a follower”- Steve Jobs

As a company we strive to find better ways to do things and continuously develop more value to our customers. Staying one step ahead and finding solutions for the problems of tomorrow. Ziptrak invests significant resources in developing blinds that offer exceptional reliability, ease of use and weatherproof protection.

OUR PROCESS STARTS WITH LEARNING

Testing our limits

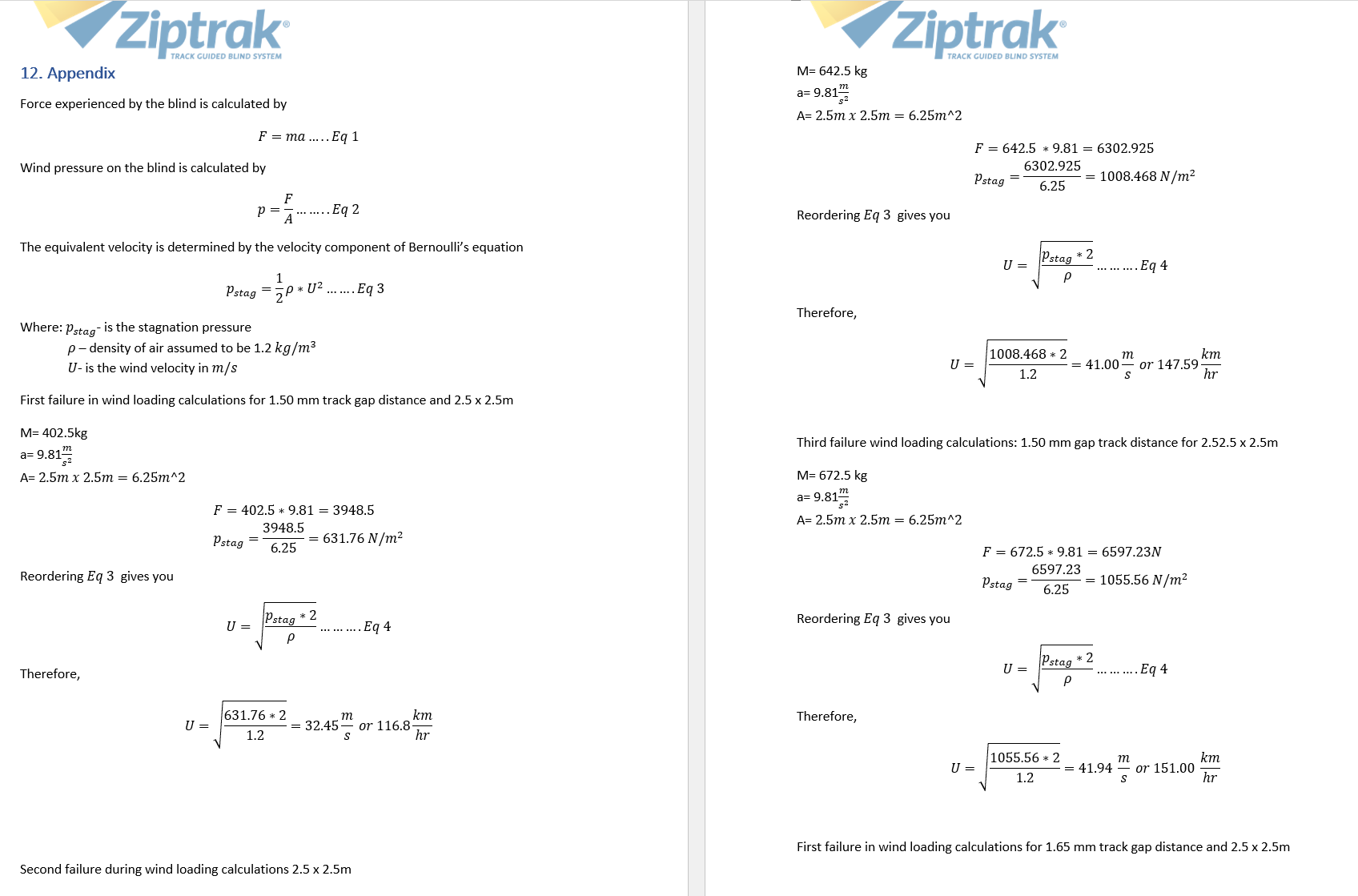

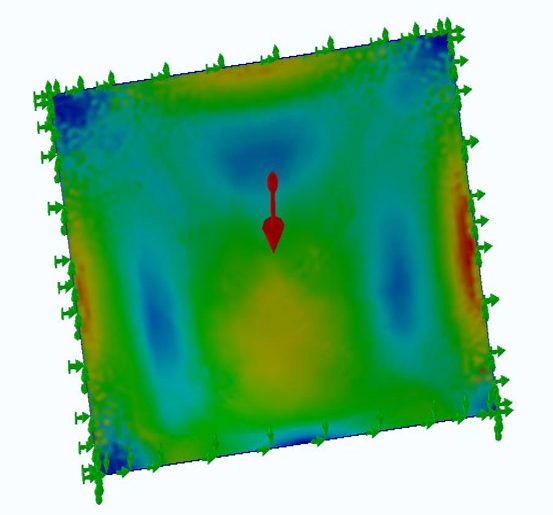

We work in partnership with universities to understand the physics behind our blinds. We continuously seek to learn and push our limits, achieving what once was thought impossible.

PRODUCT VERIFICATION

Testing – essential part of the process

All our Ziptrak® components and systems are subject to rigorous testing both in real and simulated scenarios. We ensure that the final product meets the intended specifications and quality standards. By validating the product through testing and verification processes, companies and consumers can have confidence in its reliability, safety, and performance.

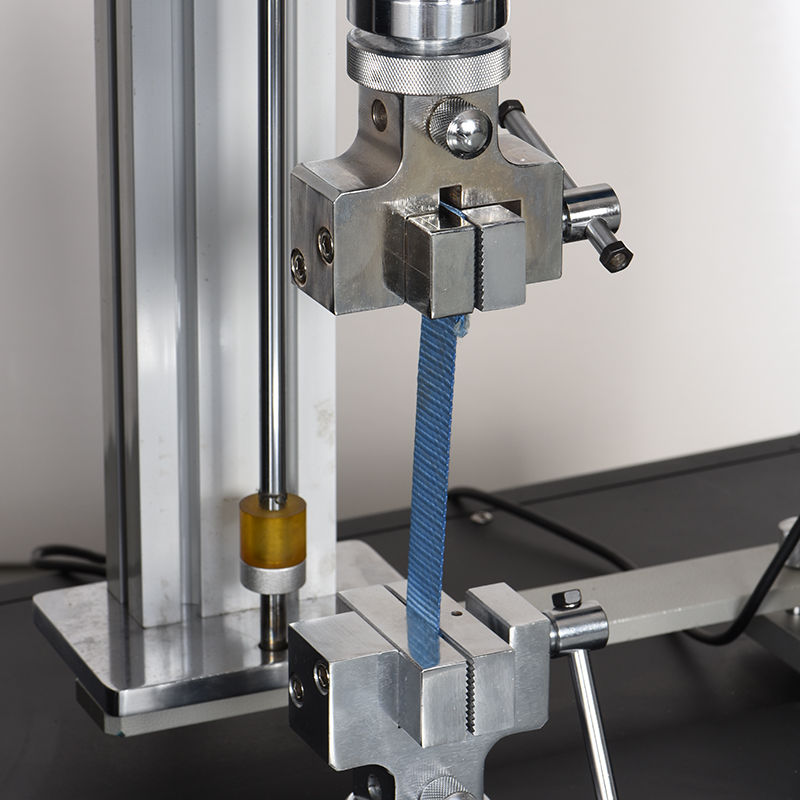

Ensuring reliability through destructive testing

We employ Destructive Testing to quantify the force necessary to induce failure in our components and to analyse the mechanisms of failure. This analysis informs design improvements. The measured failure thresholds substantially exceed the maximum strength and durability specifications required for our products and components, ensuring exceptional performance and reliability.

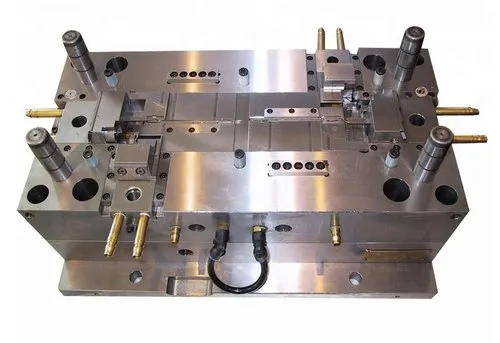

Designed for efficient manufacture

We work in partnership with our suppliers to increase our knowledge on materials and processes to ensure that we design optimal components and systems.

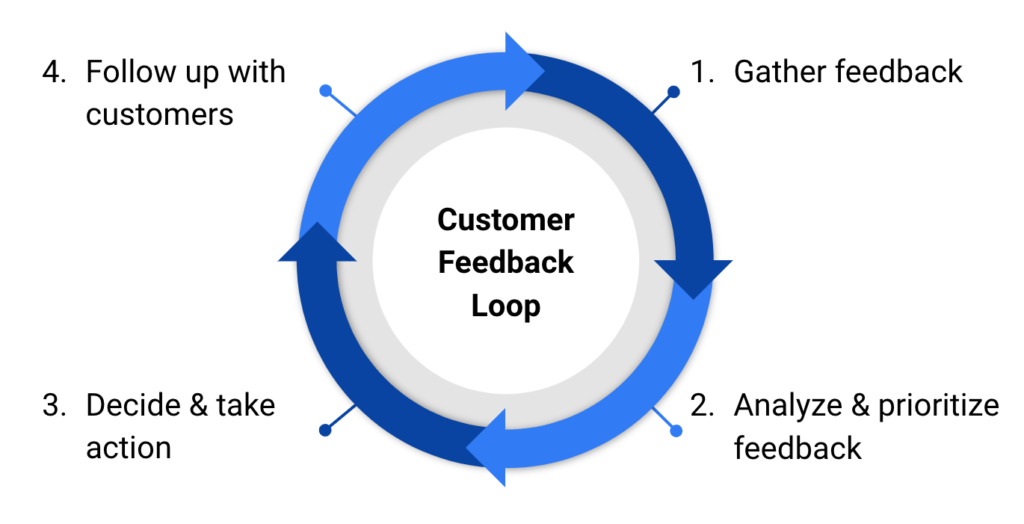

Customer Feedback

We strive to collect and analyze customer feedback in order to develop solutions to customers’ problems. We stay close to our customers and learn to think like them in every stage of our product development process.

LEARNING LEADS TO IDEAS THAT ARE TURNED INTO CONCEPTS

From Ideas to Innovations

We all have ideas, even great ones, yet few companies can bring them to life, and even fewer can turn them into innovations. At Ziptrak we spent years refining our product development process and it all start with creating and evaluating concepts.

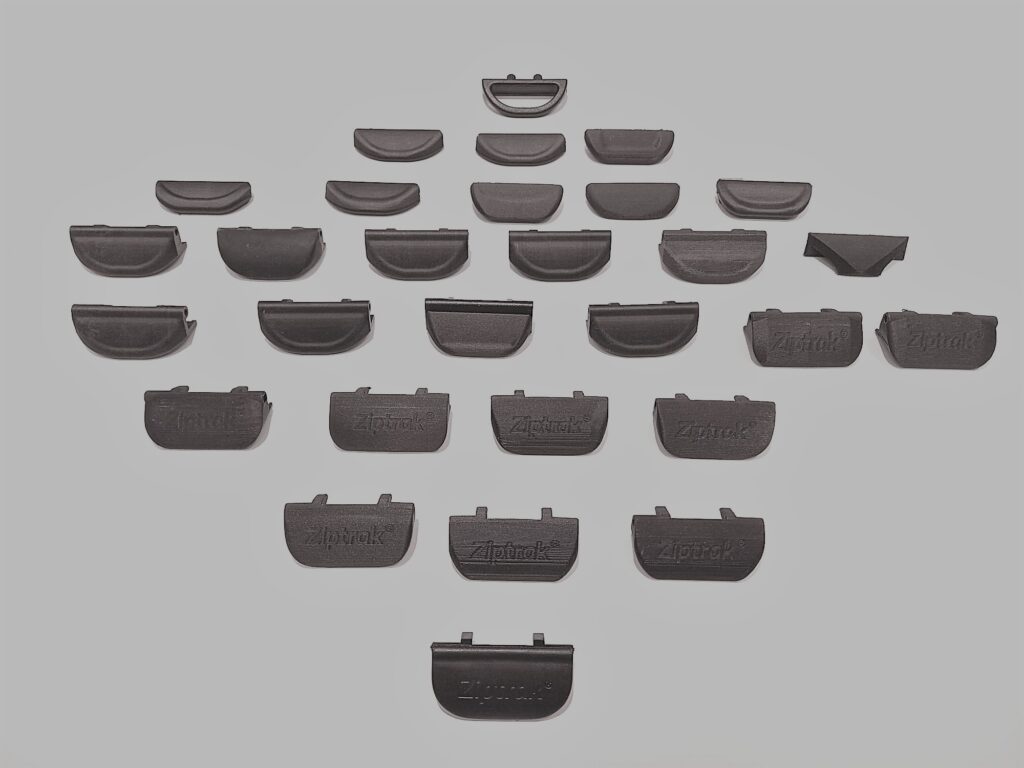

CONCEPTS ARE TURNED INTO COMPONENTS AND SYSTEMS

From Ideas to Prototypes

We use advanced 3D drawing software to design, perform simulation and check compatibilities to help bring ideas to life. Our designers use various methods and tools to translate abstract concepts into tangible and functional prototypes. This involves creating physical models, mock-ups, or digital simulations to test and refine the design.